Gasket failures can be bothersome, triggering unwanted downtime, profits loss and safety concerns. Failure analysis shows that as much as 85 percent of all gasket failures are because of malfunctioning user installation, though it is necessary to note that with proper training and installation treatments, the majority of these failures are preventable. ASME PCC-1 is a post-construction guideline for pressure boundary bolted flange joint assemblies, and the bulk of gasket manufacturers derive their installation treatments from this standard. For the end user who does not have a setup treatment, it is a terrific resource to have; however, the book is more than 99 pages and is not ideal to bring around in the field.

To aid with this, the Fluid Sealing Association, (FSA), in combination with the European Sealing Association, (ESA), have actually developed a Gasket Setup Procedures pocket book (offered in 9 languages on the FSA and ESA sites, fluidsealing.com, europeansealing.com) to help installers concentrate on the bottom lines of correct gasket setup. Following is a summary of the six primary locations of focus in sequential order.

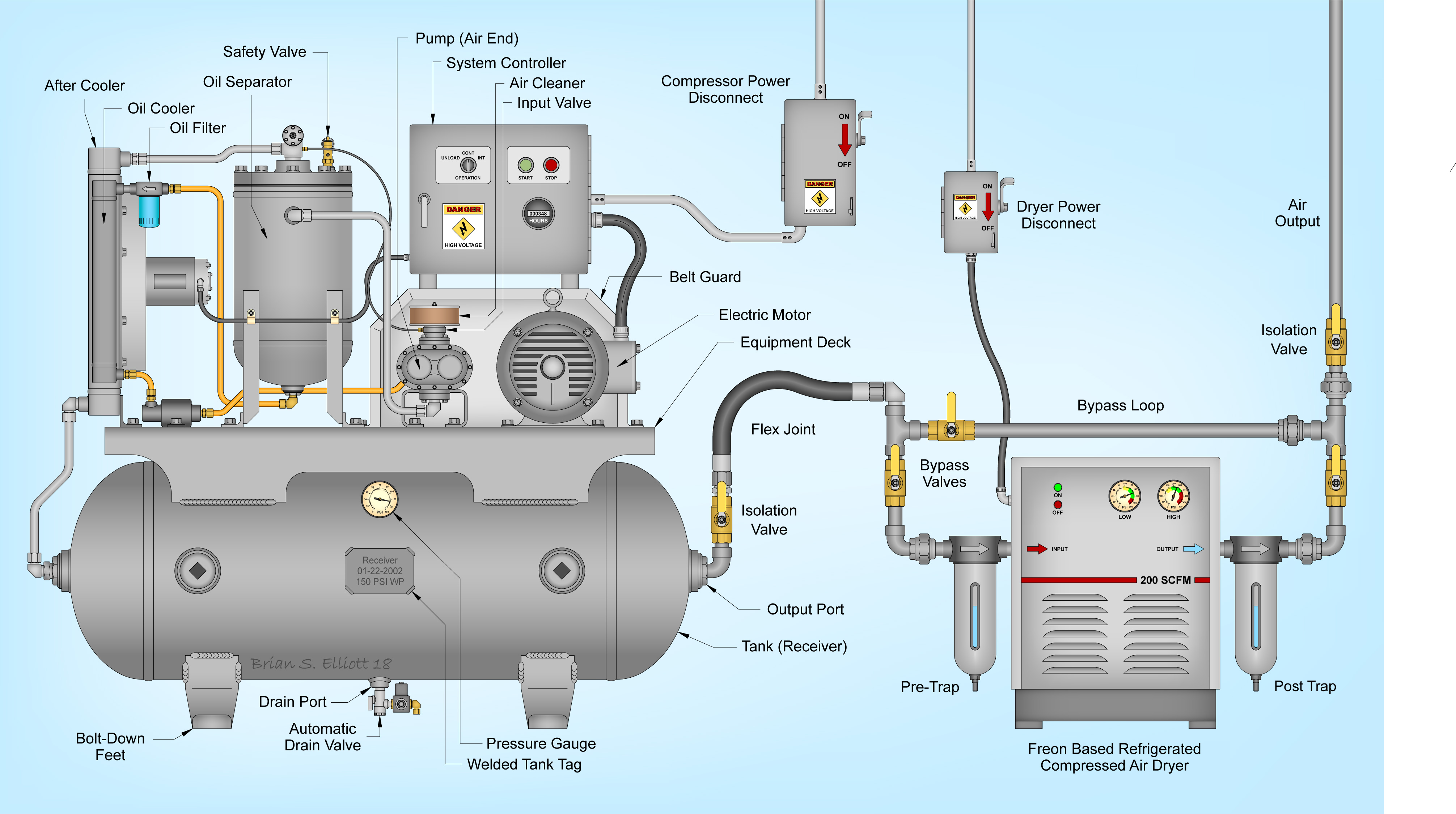

Circle tightening up illustrationFigure 1: Tradition approach or cross-bolt tightening pattern (Graphics thanks to FSA).

Prior to starting any setup, it is very important to follow all company safety treatments and policies to make sure the system has actually been depressurized, drained and de-energized (lockout and tagout treatments) and have all the required personal security devices (PPE) and tools to assist the task go as smoothly and as safely as possible. At minimum, devices should consist of:.

adjusted torque wrench or other tightening device.

wire brush.

construction hat.

security goggles and/or face guard.

lube.

other plant specified equipment.

Action 1: Clean and Examine.

Once the gasket has actually been removed from the flange, remove any foreign product or gasket particles from the sealing surface. Using a wire brush, physically get rid of any product embedded in the sealing face or flange serrations. Be cautious not to use a mill, hammer and chisel, or abrasive product that might even more harm the flange sealing surface area. Examine the sealing face for dents, dings, mars or pitting that could trigger sealing concerns. If there is any visible flange face damage, you can describe ASME PCC-1 Appendix D-- standards for allowable gasket contact surface flatness and problem depth, to determine if repair work to the flange are needed. Inspect fasteners such as bolts, washers and nuts for flaws, fractures and burrs. If fastener elements are figured out to be malfunctioning then dispose of and change.

Evaluation Pointer:.

When examining bolts and nuts, make sure http://estheticmaster.net/derrylwc7k/post-come-to-be-50768.html that nuts run freely over the threads prior to setup to guarantee there is no damage to the threads.

Action 2. Align Flanges.

To develop an efficient seal, the installer needs to ensure that the flanges are parallel as they are united. This provides the best possibility of applying a consistent optimum gasket load, developing the very best seal. ASME PCC-1-2013 Appendix E-- Flange Joint Guidelines, provides the recommended allowed limits for:.

flange parallelism.

centerline high/low (the alignment of inner diameter (ID) of the flange bore or outer size (OD) of the flange fulfill).

rotational-two hole (rotational positioning of bolt holes to allow the insertion of fasteners without binding).

excessive spacing, which is specified as when the range between the two flanges is more than twice of the gasket thickness chosen.

If the system piping requires more than typical force to bring the two flanges together, contact or talk to an engineer. Do not try and overtighten the bolts in hopes of bringing the flanges together.

Alignment Tip:.

Prevent utilizing a pry bar or screwdriver to line up flanges. Proper tools are readily available to assist with both direct and rotational alignment that are safer and much easier to utilize.

Step 3. Set up Gasket.

Prior to installing, examine the gasket to ensure that it is without flaws which it was cut easily without any rips or tears. Thoroughly place the gasket in between the flanges, making sure it is centered between the flanges. In the case of tough or horizontal setups, never use release representatives or joint substances on the sealing surface of the gasket. Doing this triggers two main issues:.

The joint is now lubricated making it easier for the gasket to extrude from the flange as an outcome of internal pressure and hydrostatic end forces that are acting on the joint.

The product can trigger a chemical attack on the gasket, jeopardizing the gasket properties and its life span expectancy.

Jay Turner Company

1012 N 1st St, Artesia

NM 88210, USA

575-746-1730